With Sustainability at the forefront of the industry, how can high-speed warehouse doors impact energy efficiency?

Sustainability, or avoiding the depletion of the world’s natural resources to maintain an ecological balance, is fundamental in modern industry concerning how products are designed and used for maximum benefit. It has been at the core of our industrial door developments at EFAFLEX since 1974!

Here are just some of the positive impacts that our industrial warehouse doors help deliver to our customer base;

- With opening speeds of up to 4 metres per second, they vastly reduce the ‘keep open’ time needed for goods, machinery, or people to pass through the industrial door. These speed up logistics but, more importantly, from an energy-saving perspective, can reduce the escape of heated or chilled air, saving energy costs by as much as 50%

- Quality fast action doors, such as EFAFLEX, can incorporate insulated door laths in their structure. Our SST high-speed spiral door, for instance, incorporates EFA-THERM® laths to improve insulation. This is a key consideration when heating or chilling an area or warehouse logistics facility; where do drafts, gaps, and energy leaks occur?

The Role of High-Speed Warehouse Doors in Pharmaceutical Industry Energy Conservation

The pharmaceutical and clean room industry have specific niche needs to ensure the air quality in production and research areas is pure, with the risk of cross-contamination kept low.

Industrial high-speed doors perform a vital role here in terms of air cleanliness and also energy conservation. Once again, those vital ‘keep open’ times are minimised due to the fast action door, opening of speeds up to 4 metres per second, reducing exposure and conserving energy.

Fast action doors equals reduced keep-open times, and therefore vast energy savings.

Maximising Energy Efficiency with High-Speed Doors in Manufacturing

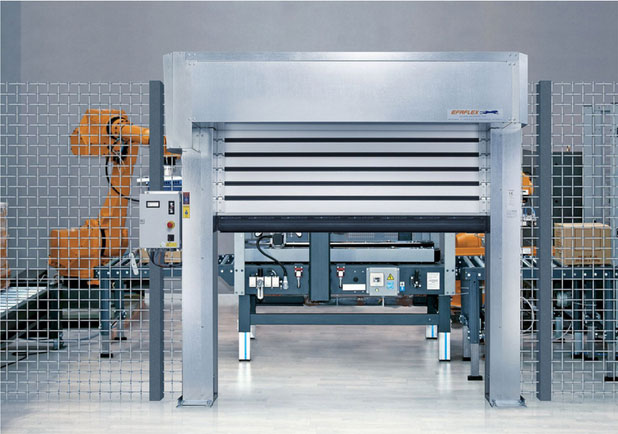

Manufacturing is a key sector for EFAFLEX, where our warehouse roller shutter doors have been designed to solve specific solutions within the realms of energy efficiency.

Here are some of the key benefits they offer;

- Their fast action, high operating opening and closing speeds increase productivity by speeding up traffic and workflow

- Their rapid roller design minimises waiting or keep open times in front of the doors and around the manufacturing facility. This in turn reduces the escape of heated, chilled, or temperature-controlled air or pressure differences while saving energy

- With a variety of automation solutions such as remote controls for operatives to activate the door from the comfort and safety of their cab, or laser scanners that detect motion in front of the door to trigger their opening, this too reduces waiting or keep open time, to limit exposure to the minimum, saving energy in the process

The Impact of High-Speed Warehouse Doors on Energy Usage in Food Production

Similar to cleanroom doors, or industrial warehouse doors, those used within food production also have their niche needs. Here hygiene is key. Air quality and ingress, or cross-contamination needs to be minimal to guarantee the quality and freshness of the food being prepared or produced. Once again, speed of efficiency is vital, and with that speed comes energy savings too!

Their fast action, opening and closing faster than virtually all of the competitor’s products, helps to minimise temperature fluctuations. Due to their unique spiral design, the keep-open and waiting times are not only virtually silent in operation but energy efficient too.

Add in the superior insulation properties of the EFAFLEX products such as the TK 100, a freezer high-speed door, designed for constant temperatures and low energy consumption, and further improvements in energy usage can be achieved.

The TK 100 is a true ‘one-door solution’ for deep freeze areas, delivering outstanding thermal insulation with the best U values of up to 0.62 w/sqmK. Ideal for operating temperatures within ±30°c, this industrial freezer door is in a league of its own!

Insulated High-Speed Doors: Their Significance in Warehouse Energy Conservation

What should you look for when choosing your industrial warehouse door? What aspects of the build quality will have an impact on energy conservation? Some of these, we know, will be quite obvious, but others are here to give an overall guide to aid that decision-making process.

First off, not all industrial doors are the same. Commercial insulated roller shutter doors are manufactured using different materials, open at different speeds, using different mechanisms, and therefore offering a variety and level of benefits.

Roller shutter doors tend to roll up in style with many manufactured using a fabric curtain. By nature, therefore, they can have gaps around their edges, and are less resistant in more challenging locations e.g., exposed, or high winds. They don’t offer the same level of insulation as more robust high-speed spiral equivalents. Heat can be lost through the fabric curtain itself, as well as around the perimeter edges.

Consider the speed of opening. How fast does the industrial door open, and as importantly, close? Operating (opening speeds) of 2 metres per second are common. But faster, more durable options exist across the EFAFLEX portfolio. Even our roll-up door, which features a ‘fabric’ curtain can be used as an exterior warehouse solution, capable of up to 150,000 operating cycles per year.

Energy conservation is a key driver for us as industrial door developments have progressed over the decades. Consider your application. What level of insulation is required at the facility, as we have varying solutions to match the need. These include the EFA-SST (high-speed spiral), manufactured using a steel profile thermal insulation lath to conserve energy.

Consider too the rest of the building where the door will be fitted. Using an insulated door will help drive down energy costs for sure, but if the nearby windows have gaps or the roof isn’t well insulated, then you could make improvements elsewhere too.

Future Trends: High-Speed Doors and Next-Gen Energy Efficient Warehouses

What is next for industrial door developments?

Sustainability is a word used throughout modern marketing messages. But…… here at EFAFLEX we have been considering the environment and how we can reduce the impact and improve the circular economy since we formed, back in 1974! For nearly 50 years our team have been using technological know-how, handed down by family generations to ensure that our products are spearheading design innovation. Matching the needs of our clients, regardless of their industry sector, whether that’s industrial freezer doors, industrial roll up doors, warehouse doors, or rapid roller shutters is at our core.

At EFAFLEX we will continue to focus on energy savings for our customers by reducing waiting time at the doors by providing a selection of effective automation methods. Touchless sensors post the pandemic are becoming increasingly popular to improve hygiene. Coupled with that, we will continue to provide the fastest door opening speeds to minimise exposure to the elements and reduce energy costs, providing EFA-THERM laths where needed for that extra layer of insulation.

We will continue to use recyclable materials and components in our products at the end of their long service life to reduce the impact on landfill. Currently, around 90% of the materials we use are of this nature, so you could say that EFAFLEX is already thinking about our tomorrow today.

The Design of High-Speed Doors: Key Features that Drive Energy Efficiency

To summarise, what are the key features that drive energy efficiency within industrial settings?

- Opening speeds – i.e., how fast the industrial door opens and closes. This will determine the keep open time and exposure to any elements. Faster operating speeds equal less open time and reduced exposure, making a significant positive impact on the energy conserved

- Design and build quality – fabric, flappy roller shutter doors by their very nature won’t be as energy efficient as those manufactured using durable steel for instance, with tighter sealing around the edges, and more durable in exposed settings to withstand strong winds

- Insulation – if the door features insulation laths in the door blade, this will have a bearing on the energy efficiency of the door, but consider too other areas that may need bolstering such as gaps around windows, or roof linings

Ready to find out more?

Browse our website to view the industrial door product range and check out our industry sector-specific case studies.

If you want to learn more, please speak to one of our knowledgeable advisors, or book your no-obligation site survey.