This topic brief will explore the significant developments and advancements in industrial warehouse door technology over the past 100 years. It will cover the evolution of industrial door materials, designs, and functionalities and the impact of technology and automation on the industry.

What are industrial doors and what is their importance within various industrial sectors?

Industrial warehouse doors typically serve several key functions within their environment; they help control or limit access to an area or space; they can aid climate control, whether that is for air quality or temperature control, they can provide security, and they can act as demarcation zones, distinctly marking one zone from another.

They are typically larger in size than residential doors due to the aperture and more durable, using more industrial materials to ensure their reliability.

Premium quality warehouse or industrial doors are built to withstand heavy use and are used in a variety of industrial applications across many sectors, which include manufacturing, warehousing, logistics, and automotive. They are essential for maintaining productivity, safety, and security in these industries by providing access control, temperature control, and noise reduction. The advancements within industrial warehouse doors have improved user safety, reduced energy costs, and helped to streamline logistic processes.

Learn about the evolution of industrial door materials.

Historical overview of industrial door materials

The materials used to manufacture industrial doors have evolved over time from heavy wood, which was readily available, to now using lightweight metals that help improve the door opening speeds and durability. In the early 20th century, industrial doors were primarily made from wood, which was heavy, prone to warping and not very durable. In the 1950s, steel became popular for industrial doors due to its strength, durability, and fire resistance. Later with technological advancements, industrial shutter doors were constructed from aluminium in the 1960s as a lightweight alternative to steel. In the 1970s, with the introduction of composite materials, warehouse industrial doors became made from fibreglass and reinforced plastic which offered a balance of strength and lighter to operate. In recent years, glass has also become a popular option for industrial doors due to its aesthetic appeal and ability to provide natural light to enhance working conditions and user safety.

Advances in materials science have led to the development of high-performance materials that offer improved energy efficiency, sound insulation, and resistance to weather and corrosion. The lighter weight materials and improved design engineering have seen commercial roller shutters improve in their operational speeds too, which reduces the ‘keep open’ time and, in turn, reduces energy costs.

The impact of material advancements on the warehouse door strength, durability, and energy efficiency

Advancements in industrial door materials have led to improvements in door strength, durability, and energy efficiency. Steel doors, for example, offer high levels of strength and durability, making them ideal for high-traffic environments. However, they can also be heavy and less energy efficient than other materials. Aluminium doors on the other hand tend to be lightweight and more energy efficient, but with the added benefit of the strength of steel doors. Composite materials offer a good balance of strength, durability, and lightweight design, while also providing better energy efficiency than steel doors. Advances in insulation and weather-sealing technologies have also improved the energy efficiency of industrial doors, helping to reduce heating and cooling costs for businesses. Overall, the choice of material for industrial doors will depend on the specific needs and requirements of the business or industry, including factors such as strength, durability, energy efficiency, and cost.

Here at EFAFLEX we have designed a number of industrial shutter doors, each bespoke for the application and solution required. We have, for instance, an insulated freezer high-speed door which is the first true one-door solution for chill to deep–freeze zones. Each of our rapid roller shutter doors has been designed to operate up to 250,000 cycles per year for durability and extended service life.

Sustainability is key in today’s industrial world. The fast action opening speeds of EFAFLEX roller shutter doors mean that ‘keep open’ times in large warehouse applications are minimised. Energy costs can be reduced by as much as 70% due to the materials we use within our design and the construction of our fast-action shutters.

Learn about the development of industrial door designs

Historical overview of industrial door designs

The design of industrial doors has evolved over time to meet the changing needs of different industries. In the early 20th century, most industrial doors were simple, one-piece designs that opened manually. They were labour-intensive and slow to operate. In the 1950s, sectional doors became popular, consisting of multiple hinged panels that could be raised and lowered vertically and often referred to as overhead sectional doors. Rolling doors, which use a coil-up design to save space, also became popular around this time. In the 1960s and 1970s, sliding doors were developed, which open horizontally to the side, making them ideal for environments with limited headroom.

Industrial high-speed doors were first developed in the 1980s and designed for performance. They open and close quickly to improve efficiency and reduce energy loss. In recent years, technological advancements have enabled the development of automation systems for industrial doors, including sensors, controls, and safety features. Today, commercial warehouse doors are available in a wide range of designs, including sectional, rolling, sliding, and high-speed doors, each with their own benefits and applications.

EFAFLEX, as the market leader within industrial high-speed warehouse doors, evolved ahead of the competition. Employing generations of staff, where knowledge and skill are handed down through the generations, means that specialism is at the core of our success. Listening to our customer’s needs and truly understanding their requirements sees us adapt and change the design of our industrial shutter doors to improve user safety, and security and drive logistic process efficiencies.

Technological and Automation Advancements in Industrial Doors in the last 100 years

The rise of automation in industrial door operations.

Over the past 100 years, there has been a significant rise in the use of automation within industrial door operations. Initially, industrial doors used heavy chains to open and close, which were labour-intensive, but with the advancements in technology and machinery this has led to the development of automated systems.

By the 1920s, electric motors had been introduced, allowing for easier and more efficient operation. Throughout the mid-1900s, hydraulic and pneumatic systems were developed, which provided even more power and precision.

In the latter half of the 20th century, computer technology allowed for even greater automation and control. The development of programmable logic controllers (PLCs) and software allowed for precise control of door operations, as well as the ability to integrate doors into larger automated systems.

Today, industrial doors are highly automated, with many features such as sensors, remote control, and even internet connectivity. This allows for increased efficiency, safety, and control over door operations. As technology continues to evolve, it is likely that industrial door automation will continue to advance, leading to even greater efficiency and precision in the future.

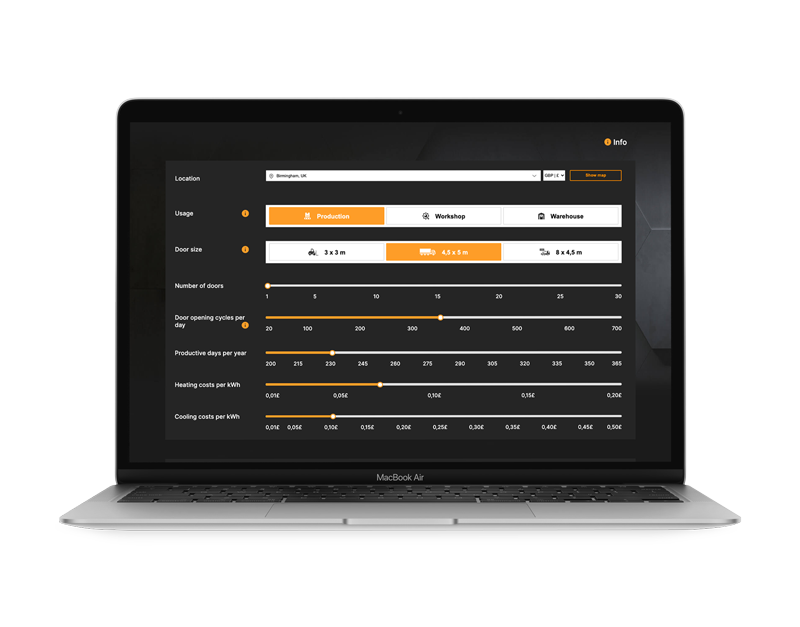

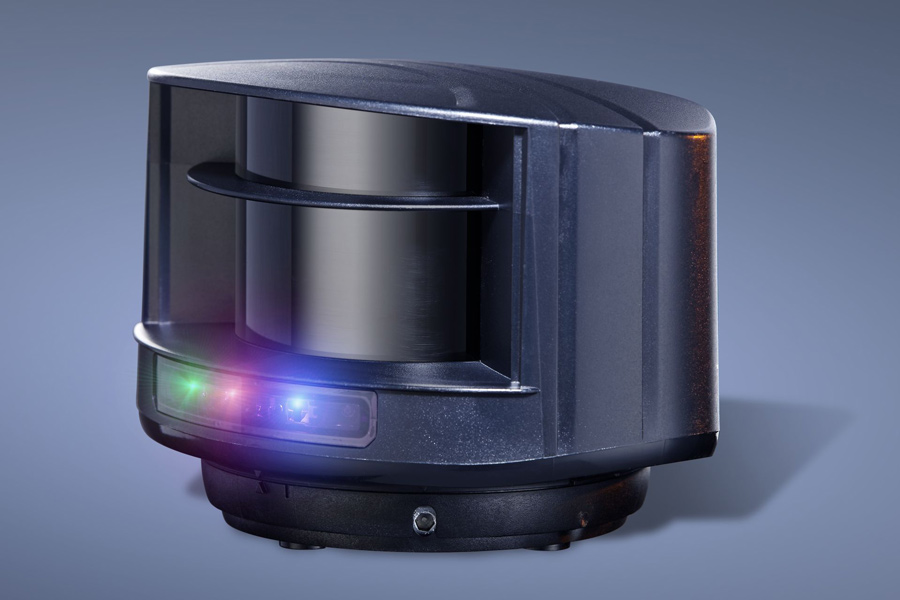

As you would expect from EFAFLEX, we have developed a range of automation methods, each designed bespoke for application and use. We were the first company to use laser scanners within high-speed industrial doors, and now offer a range of door controls which include lasers, scanners, induction loops and remote controls.

Learn about the impact of technology with modern industrial doors with energy efficiency, productivity, and safety.

Regarding productivity, modern industrial doors can be integrated with larger automated systems, allowing for seamless operation and increased efficiency. Advanced sensors and software can detect and analyse data on door usage, allowing for predictive maintenance and early identification of potential issues that could impact productivity.

Finally, the impact of technology on industrial door safety cannot be overstated. Advanced safety features, such as sensors that can detect obstructions or people in the path of the door, have significantly reduced the risk of accidents and injuries. Remote monitoring and control also allows for immediate response to potential safety hazards, further improving overall safety.

Overall, the impact of technology on modern industrial doors has led to significant improvements in energy efficiency, productivity, and safety. As technology continues to evolve, it is likely that these benefits will only continue to grow, making industrial doors even more efficient, productive, and safer to use.

For 50 years, EFAFLEX have specialised in design, installation and maintenance of high-speed performance industrial doors. The industrial door developments during this time have been substantial and significant. We have a history of firsts; the first company to design a spiral vertically opening door. The first laser scanner for doors. The first thermal laths. And we remain the world’s fastest vertically opening spiral door.

If you are looking for an industrial door solution that will be an asset to your business for now and years, then look no further. EFAFLEX ….. the original and still the best.

Ready to find out more?

Browse our website to view the industrial door product range and check out our industry sector-specific case studies.

If you want to learn more, please speak to one of our knowledgeable advisors, or book your no-obligation site survey.