Welcome to “Discover the Modern Types of Warehouse Doors,” where we’ll delve into the captivating realm of industrial door solutions! In today’s rapidly evolving logistics landscape, warehouses necessitate robust and efficient entrances to ensure seamless operations and maximize productivity. From lightning-fast high-speed doors to temperature-regulating insulated doors, we’ll explore the cutting-edge advancements in warehouse door technology. Uncover how sectional doors with intelligent automation systems bolster security and save space, or how warehouse roll-up doors endure harsh environments while facilitating easy access. Prepare to unveil the secrets behind these contemporary wonders and gain a profound understanding of the doors that safeguard the bustling hubs of global commerce.

Warehouse Roll-Up Doors

Roller shutter doors, or roll-up doors, have a long history that dates to the 1880s when the original shutters were constructed from wood with movable individual slats. They proved popular for homes and commercial use within Switzerland, where they originated by designer Anto Greisser.

Since then, warehouse shutters or industrial shutter doors have advanced but still serve the purpose of providing security and helping to reduce the risk of burglaries within shops, businesses and homes. In the main, the roller shutters were manually lifted (opened and closed).

Move on a few years, and the roller doors replaced previous revolving doors and were used as warehouse shutter doors to help improve logistics and security.

The Main Benefits and Drawbacks of Roll-Up Doors for Warehouses

Roller door shutters offer many benefits for warehouses;

Here are just some;

- Security – to help prevent the risk of theft and vandalism

- Insulation – to help keep warehouses warmer in the winter and reduce energy costs

- Weather protection – insulate against harsh weather conditions

- Increased safety – particularly with electrical rolling doors that don’t rely on manual operation

In terms of drawbacks, these include;

- Cost – the outlay of the initial fast action shutter, so check the manufacturer’s warranty prior to purchase

- Maintenance – roller shutter doors do require regular maintenance to ensure they function properly

- Noise – some roller shutter doors can be quite noisy; again, seek a demonstration before purchase.

Sectional Warehouse Doors

A brief overview of sectional doors and their features

Sectional doors are used to describe doors made using sections or laths and are typically used in a garage environment with a vertical opening to create free space in front or behind the door.

Learn about the main benefits and drawbacks of sectional doors for warehouses.

Sectional doors offer a popular choice in the UK for home and commercial environments with features that include;

- Weather sealing – to help protect from the elements

- Customisable – they can be customised to match a particular colour, finish or window option

- Durable – and space efficient to aid the efficient flow of goods into and out of buildings

- Insulated – some are insulated, which helps with climate control and energy saving

Here are some of the most common problems encountered when using sectional warehouse doors;

- Maintenance – due to their nature (sections of laths), they do require regular maintenance to function properly

- Cost – they can be expensive when compared specifically with alternative garage doors

- Safety – care should be taken when using sectional doors which don’t have a safety cable break device.

High-speed warehouse doors

An overview of high-speed doors and their features.

Rapid-rise or high-speed doors are effective industrial door solutions designed to improve user safety, reduce energy costs, and enhance the security of a warehouse or commercial setting. They are technically advanced versus sectional doors or rapid roller shutter doors. They are designed to improve workflow, speeding up logistics, with their fast action minimising ‘keep open’ times to reduce exposure to the elements, saving energy costs for heating or climate control.

Industrial automatic doors are high-performance with benefits including;

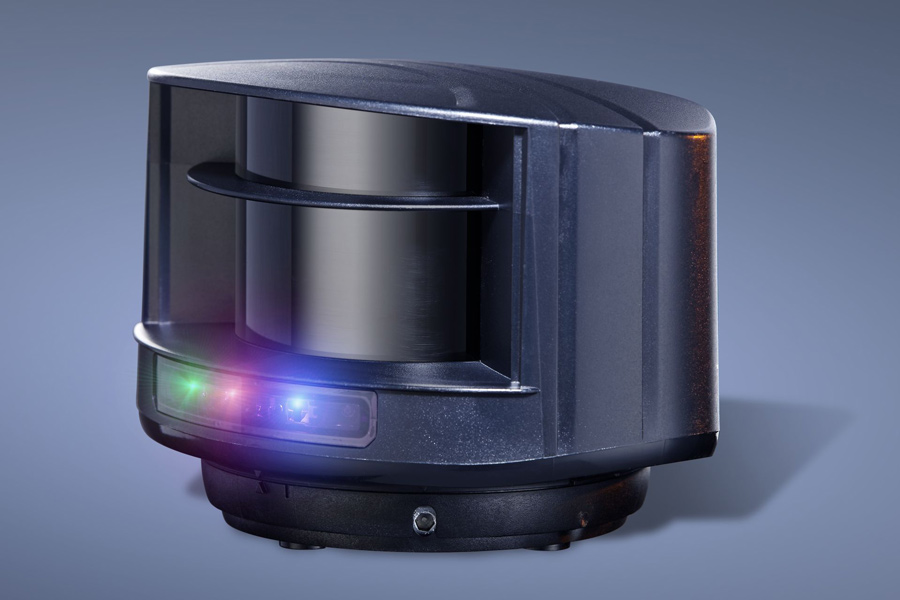

Improved efficiency – their fast action reduces waiting times at loading bays and around warehouse facilities, with sensors that can speed up logistics, e.g., remote control or laser scanners

Improved insulation – insulated laths can help to reduce energy costs significantly

Improved user safety – visibility panels, or vision windows can help improve the line of sight for work operatives, e.g., forklift truck drivers, to minimise the risk of incidents

Learn more about the benefits and drawbacks of high-speed doors for warehouses.

Drawbacks include;

Perceived cost – they are initially more expensive to purchase compared to lower specified metal shutter doors, but once their whole life costs have been assessed (extended service intervals, significantly reducing energy costs and minimising costly downtimes), they are considered an asset to a business.

What is the installation and maintenance process for high-speed doors with EFAFLEX UK?

Our team of trained engineers completes the installation of an EFAFLEX high-speed warehouse door.

Regular preventative maintenance will increase its service life and reduce the risk of unwanted downtimes. The service intervals are partially determined by the number of operating cycles your EFAFLEX high-speed door completes each year.

All spare parts are genuine EFAFLEX products for extra longevity and improved performance.

Bi-Folding Warehouse Doors

Bi-folding doors are also known as folding sliding doors, which are manufactured from multiple panels that slide open, concertinaing together into a stack on either end of the opening. Thanks to their static panel, they work well where sliding doors might restrict movement or airflow.

They can be used for exterior or interior use and are a modern alternative to older French-style patio doors in domestic settings.

The main benefits and drawbacks of bi-folding doors for warehouses

Concertina industrial doors, or bi-fold doors, have numerous benefits for warehouses, including;

- Flexibility – they can be opened inwards or outwards depending on the requirement, working well in both large and smaller spaces

- Light – due to their nature, they provide a great deal of natural light

Drawbacks include;

- Maintenance – they generally require more maintenance than high-speed, high-performance industrial warehouse doors. The nature of the structure means that the frames can break up and interrupt views when used on domestic projects.

Vertical-Lift Industrial Doors

Vertical lift doors are typically used within warehouse environments. also known as overhead doors or vertical rise doors, are a popular choice for large-scale industrial and commercial warehouses.

The main benefits;

One of the critical advantages of vertical lift warehouse doors is their ability to provide complete vertical clearance when opened, allowing easy access for tall vehicles and heavy machinery.

Some of their features include;

- Durability – they can withstand high wind loads and extreme environmental conditions

- Flexibility – depending on the design required, they can be used as a single or multiple-panel design

- Cost efficiency – if manufactured to a high specification, they can be insulated with non-CFC polyurethane, which provides thermal control by reducing temperature leakage.

Modern Warehouse Needs for Soundproof Doors.

Some warehouses may require soundproof doors to reduce noise pollution, preserve residential peace or create a more comfortable working environment, but specifically where sound is a primary concern, e.g., in heavy manufacturing facilities.

What are the benefits and drawbacks of soundproof doors for warehouses?

The most obvious benefit of a soundproof warehouse door is the noise reduction to reduce outside noise and control acoustics to provide workers with a more comfortable working environment.

Additionally, they can help to improve air quality by preventing dust of pollutants from entering the warehouse. They can also aid with moisture and humidity control.

Our Advice On Factors to Consider When Choosing Warehouse Doors

Learn how the size of a warehouse affects the choice of industrial doors.

The cubic volume of a warehouse does affect the choice of door. When making your commercial roller shutter door selection, consider the type of vehicles used within the facility. Larger warehouses may need larger openings to facilitate the traffic flow and movement of goods. Not all manufacturers of high-speed doors can design and build to larger sizes, and if they do, then quite often, the speed of opening and closing is compromised as a result.

The choice of a door should reflect how the warehouse is being used. Consider the volume of traffic, and the nature of the goods being transported, e.g., does the warehouse require insulated industrial doors or is the warehouse exposed to extreme environmental or climatic changes that will impact the speed of the fast action door required?

All EFAFLEX high-speed doors are custom built to match the customer’s specific needs.

The process begins with an expert no-obligation site visit

Our no-obligation site visits to start each project. Here one of the experienced team will visit the site and hold a lengthy discussion with the client to understand the specific and unique requirements fully. This conversation will include the following;

- How the facility is being used

- How many operating cycles the door needs to perform in any given year

- What is being stored within the facility

- How secure does it need to be

- Are there any additional considerations, such as exposed sites potentially impacted by strong winds?

This complete ‘diagnosis’ and process helps ensure the right fit for the customer’s immediate and longer-term needs. During the discussion, we may use the door configuration app. This builds the picture of how the high-speed door will look aesthetically and demonstrates the real-time speed of the door type on screen so that the client can better visualise the result.

EFAFLEX has an extensive range of products: spiral doors, fabric roll up doors or folding in design. But these broad ranges have unique features that benefit differing industrial sectors. For instance, the cleanroom (CR Series) features smooth surfaces to reduce the risk of dust or particles settling and minimise contamination. The TK 100 Thermal door features insulation laths, making it a true one-door solution for deep freeze zones.

Every project follows a similar workflow; site visit, measure, design, build and installation, but each has individual idiosyncrasies. That level of detail, passion, and innovation makes EFAFLEX the global champion of performance industrial doors.

Key factors to consider when selecting doors based on warehouse size.

Selecting and purchasing an industrial automatic door requires careful consideration. It is a commercial decision that should quickly become an asset to your business in terms of energy efficiency, user safety and durability. Not all high-speed warehouse doors are the same. Not all high-speed industrial doors use the highest quality materials or can operate at the super speeds reached by EFAFLEX.

Here are some thoughts on what to consider when making that choice;

- Where is the warehouse located?

- Will the industrial doors be positioned internally or externally? This will make a difference in terms of if a fabric roll up doors is sufficient or if a more durable industrial roller shutter may be needed

- How is the warehouse being used? What is being stored in the facility will make a difference to the type of industrial warehouse door you’ll need e.g. cleanroom facilities have a totally different list of requirements to say, a car park facility.

- Does it need to be an insulated door?

- Is the speed of opening a determining factor to reduce ‘keep open ‘time?

- What is the volume of traffic that will be using the door? Consider how many operating cycles the door needs to be able to perform a year to reduce costly downtime and lengthen the period between service checks

- Who is using the facility? If machinery and staff use the warehouse, visible transparent laths would be beneficial. These improve the line of sight for, say forklift operatives between the work areas to help reduce the risk of accidents.

Not all high-speed door manufacturers have the experience or capability to design and build larger sized warehouse industrial doors. Many provide off-the-shelf solutions in sizes that are fixed. At EFAFLEX, all of our high-speed industrial doors are made to measure and built to feature those requirements that are specific to that project.

Our industrial door products, including cleanroom doors, car park doors and warehouse doors, are all custom-built. We have manufactured high-speed doors for niche applications, including railway stations, emergency services and airport hangars, where the requirement means the doors need to be super-sized but still high–speed in operation.

Guarding the Goods: Modern Warehouses and their Increasing Security Needs

High-speed, high-performance warehouse doors have many applications, from the normal to the niche. Our products are specified globally for their durability, performance, safety, and security features. Depending on how the warehouse is being used and what is being stored will affect the type of door required. Take, for example, one client in Turkey where precious inks are held to produce bank notes; their requirement has a different security need than, say, a food producer who is storing grain. The need for a high-speed warehouse door is similar to restrict access, but the level of security the door provides is different.

At EFAFLEX we have a range of industrial doors for all levels of security, from the lower fabric roll-up door ideal for interior use to the classified WK 2 and WK 4, which offer resistance Class RC 4 where the risk of burglary or theft is more significant.

Consider your warehouse’s purpose, what is being stored, and its location. These factors will help determine what level of security industrial door is required; EFAFLEX has a product solution to match.

The main factors to consider when selecting doors based on security needs.

The EFAFLEX range of high-speed roller shutter doors is each designed for a different level of security.

Our fabric roll-up doors offer an excellent price-performance ratio. They are ideal for interior use and often used to demarcate areas of work. The fabric is durable and high quality but obviously offers a different level of security than our turbo high-speed spiral doors. These are manufactured using premium materials that provide the fastest opening speeds to reduce ‘keep open’ time and reduce the security risk.

Within the industrial door range we have a number of niche products for specialist applications. These include machine protection high-speed doors whereby the doors are used to safeguard operatives from machinery and help reduce the risk of accidents.

Across the industrial door range we offer a full spectrum of security levels, from the fabric lighter-duty roll-up doors, through to metal doors that offer burglar protection or even explosion protection.

Keeping Pace: The Demands of Modern Warehouse Traffic Flow

How a warehouse’s traffic flow needs will affect the industrial door choice.

Traffic flow refers to the movement of goods and people within a warehouse. These differ enormously depending on the use of the warehouse facility. Food and beverage facilities will typically have more movement of goods as they travel around the facility at goods inwards and dispatch. Other warehouses may be storing goods that aren’t as mobile.

The traffic flow will determine the type of door which is most appropriate. The choice of the door will also be determined by the type of traffic flow, i.e. what is using the high-speed door.

Higher volumes of traffic flow will require a more durable high-speed warehouse door. EFAFLEX industrial doors are capable of up to 250,000 operating cycles per year. In the context of service and maintenance schedules, you’ll soon realise how EFAFLEX doors extend the time required between servicing. Take that one stage further, and you’ll appreciate that the longer service intervals equate to less downtime, i.e., when the warehouse is non-operational.

Here at EFAFLEX, all of our industrial automatic doors are built to last. The minimum number of operating cycles the lower specified doors can complete is 150,000 cycles per year, with the maximum up to 250,000 per year.

When choosing your high-speed industrial door, consider the traffic flow. How durable does the door need to be? How quickly does it need to open?

When selecting your industrial door whether it’s for a cleanroom, car park facility, or a goods inwards, consider what and who will be passing through.

Does it need to incorporate vision panels (transparent laths) for extra line of sight? These are particularly popular when a heavy traffic flow of forklifts and machinery operates.

Will pollution be an issue, e.g., car fumes from car park facilities, and if so, we can supply doors with ventilation laths?

What vehicles will be using the entrance? Cater and plan for the largest size to future-proof your facility.

Think of what and who will be the traffic flow and combine this with the frequency of use and the level of security needed. These will help determine your choice.

EFAFLEX have a range of high-speed warehouse doors to suit virtually every warehouse application, from deep-freeze to machine protection, cleanroom to logistics.

Here are some examples of where our industrial doors can be used depending on the traffic flow.

Our fabric roll-up doors are ideal for interior use. They can cope with high traffic volumes and can operate up to 150,000 cycles per year.

Our spiral high-speed doors typically open and close at speeds up to 4 metres per second. This reduces the ‘keep open’ time and minimises exposure to the elements. They are ideal for areas with higher traffic flow volumes as their fast action means less waiting time for operatives.

Regardless of your traffic flow needs, we have a product solution to match.

Are you eager to learn more?

Take a look at our website and explore our diverse range of industrial door products. While you’re there, delve into our collection of warehouse door solution case studies tailored to specific industry sectors.

If you’re hungry for further knowledge, our team of experts is ready to assist you. Feel free to contact our knowledgeable advisors for more information or schedule a no-obligation site survey to discover how our solutions can meet your specific needs.

Get ready to unlock a world of industrial high speed warehouse door possibilities!