Warehouse shutters, often referred to as ‘roller shutters’ can point their origins date back to the 1st Century AD and later to the Romans who used marble shutters to control light, and provide privacy. Fast track to the industrial revolution of the 1700’s when shutters were needed due to a shift in working patterns and the use of new materials including iron and steel saw roller shutters being used to provide security and privacy. Look nearer to the 1960’s and the modern day roller shutter as we now recognise it, was born.

During the last few decades roller shutters have evolved. What were labour intensive warehouse shutter doors, which relied on heavy chains to open them manually, have developed into sophisticated high performance doors with gadgets to assist and automate and improve safety in the door opening.

Not only have the opening mechanism altered during this time, but factory doors have evolved as health and safety requirements have become more stringent. Quite often, heavy plant and equipment mix and combine in areas where people operate in fast paced, busy environments such as warehouses and logistics operations. Accidents and incidents can occur.

How has EFAFLEX evolved to become the global market leader in industrial high speed doors?

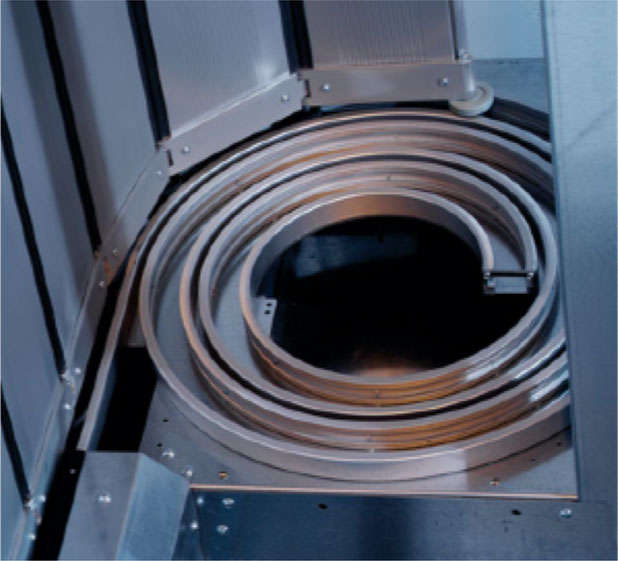

Established for 50 years, EFAFLEX were the first and only company worldwide that specialised in fast action industrial shutters; originally, in 1992, we introduced the first spiral high speed door. It is a style which has been copied by many, but the design remains the world’s fastest vertically opening door to this day!

With experience comes expertise and knowledge. Over the decades, as industrial sectors have evolved, so too have our customer’s requirements for often bigger, better, faster, and more insulated roller shutter doors. The clean room industry, for example, has a specialist requirement for industrial high speed doors which are hygienic and easy to clean. Internal doors differ from their external counterparts and may be manufactured using a fabric curtain which doesn’t require the same insulating properties or wind resistance. Whereas in car park environments, the headspace may be reduced or limited and need a different oval shaped opening style.

The constant desire for innovation has remained the same throughout our development; for EFAFLEX to evolve ahead of its competitors in terms of usability, reliability, and performance.

The warehouse spiral door opening design is still our most popular product globally. But with progress comes evolution, and here at EFAFLEX, we aim to be ahead of the curve, a company of firsts that continually reinvests in our people and products.

Our range speaks volumes. Fundamentally we have three key door styles that either spiral to open, fold (or concertina), or roll up and are manufactured using a heavy duty fabric. Each model has options to suit the customer with specialist niche features such as viewing windows, transparent laths or heavily insulated panels.

From our beginnings in the 1970s, we have innovated, designing unique products with the customer’s needs at its core. 2012 saw the introduction of the TK100 – this first truly one door solution for deep freeze areas. The CR Series was designed specifically to cater for the needs of clean rooms to guarantee airtightness and air cleanliness with its smooth, easy to clean surfaces. Or the MTL door – designed for the Material Transport and Logistics sectors.

It’s hardly surprising that around 60% of our annual sales are to replace old fashioned, slower, less functional industrial roller shutters for our high performance alternatives.

What were the issues experienced by warehouse managers in the 70s with factory roller doors?

Back in the 1970’s, there was little choice. Roller shutter doors were similar in style and typically operated using heavy, cumbersome chains to haul the door open manually. This was labour intensive and slow, exposing the building to the elements for long periods. They were prone to breakdown, jam or worse, still get damaged, leading to costly downtime while the door was waiting to be repaired. This would have a knock-on effect. Production might have to be halted, for instance, in manufacturing plants, leading to costly delays.

The industrial roller shutter of the 1970’s had virtually no insulating properties, fundamentally intended to offer security and protection for warehouses and their goods. Poor insulation led to temperature fluctuations, which is not ideal when processing products that require a constant temperature, such as in food production or the pharmaceutical industry.

Lack of ventilation within factory buildings could lead to poor air quality, with dust and dirt building up and equipment malfunctions. Inadequate lighting could lead to an increase in accidents and injuries.

The issues facing warehouse managers in the 1970s varied, but all were costly, a huge inconvenience, or both!

Detailed reasons why a warehouse manager would need a High-Speed Roller door to improve factory safety and processes

There are many reasons how a high speed commercial roller door will help improve safety and drive logistics improvements. Here are just some;

- Increased efficiency: as the high-speed roller doors open and close quickly, (up to 4 times faster than a conventional sectional or roller door) this reduces the waiting time of vehicles and equipment, entering or exiting the warehouse. This can help to increase overall efficiency and productivity.

- Temperature control: high speed roller doors with their insulating door laths and speed of operation can help to maintain a consistent temperature within the warehouse. This can be especially important in environments where temperature control is crucial, such as in food production or pharmaceutical processes.

- Security: high speed roller doors can be equipped with security features such as remote control access, security cameras and alarms, which can help to prevent unauthorised access and increase security.

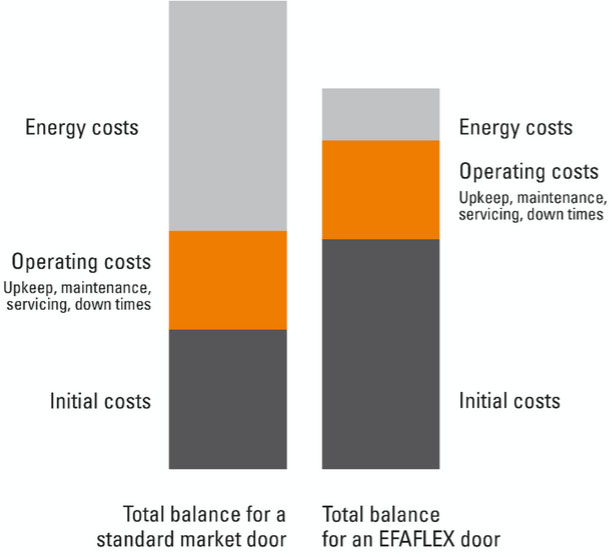

- Durability: high speed roller doors are typically made from durable materials that are intended to withstand repetitive and frequent use and exposure to the elements. This can help to reduce the need for repairs, with longer periods between service and maintenance checks resulting in cost savings over time.

- Energy savings: high speed roller doors can help to keep the warehouse more energy efficient by reducing the ‘open time’ and the amount of outside air that enters the building, which can help to reduce heating and temperature control costs.

- Safety: high speed roller doors can be equipped with safety sensors and integrated monitoring systems, which can help to prevent accidents and injuries.

How can EFAFLEX help modernise your warehouse with industrial shutter doors?

There are many ways in which your warehouse can be modernised by installing an EFAFLEX industrial shutter door. First off, the appearance and aesthetics. Many of the EFAFLEX door options can be matched to a RAL or Pantone reference number to coordinate with a corporate look or design. Our warehouse fabric roll up doors can be printed using your own custom image to blend or enhance a theme.

Looks aside, the functionality of any EFAFLEX fast action shutter is a key deciding factor when making a purchase. The high speed doors open and close effortlessly, almost balletic in their movement and virtually noise free. Speed is key. This leads to so many other contributing factors for today’s warehouse doors. Speed means less waiting time for drivers and at loading bays. Speed means less open time and exposure to the elements. Speed means an increase in productivity.

Safety is always uppermost in our high speed door designs. The modern warehouse environment is a bustle of activity, where man and machine have to work side by side. The vision laths in our doors increase not just the amount of daylight to improve the modern working environment, but also give that line of sight to the people passing either side.

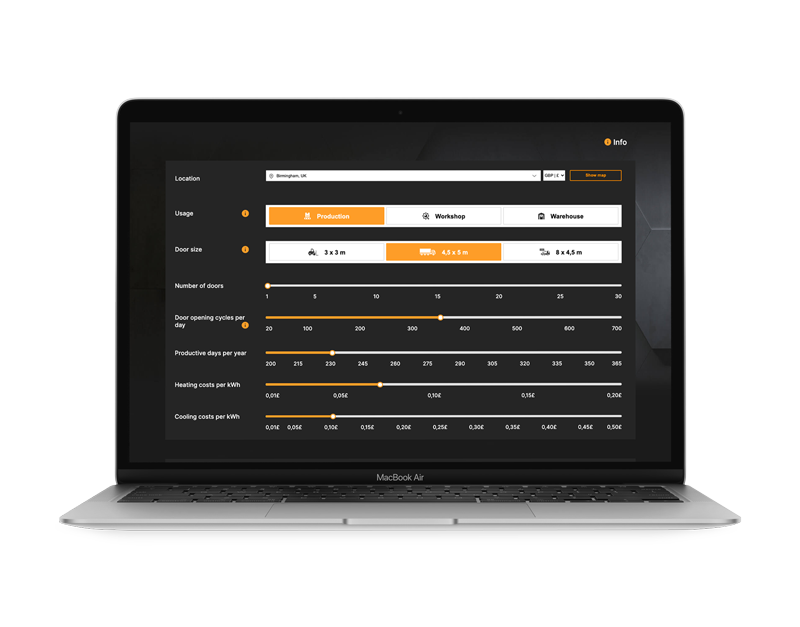

Automation is a key area where we can help modernise today’s warehouse.

With a variety of warehouse door options for users which include laser scanners, infrared, remote control and even contactless ‘wave options’ to improve hygiene.

Today, probably more so than ever before, we are conscious of the environment. Not just our impact upon it, but from a sustainability aspect. Our door products are designed to use materials and processes that will help reduce carbon footprint, from the raw materials we source, the manner in which our goods are packaged and transported, through to their eventual end of life with materials selected for recycling or reuse.

No discussion, though, would be complete without including energy usage. An EFAFLEX high speed factory or warehouse door can help reduce energy usage by up to 25%. You could say that EFAFLEX has it all….. style, good looks, performance, and functionality to improve safety, and security and reduce energy usage.

Ready to find out more?

Browse our website to view the industrial door product range and check out our industry sector-specific case studies.

If you want to learn more, please speak to one of our knowledgeable advisors, or book your no-obligation site survey.